Technology

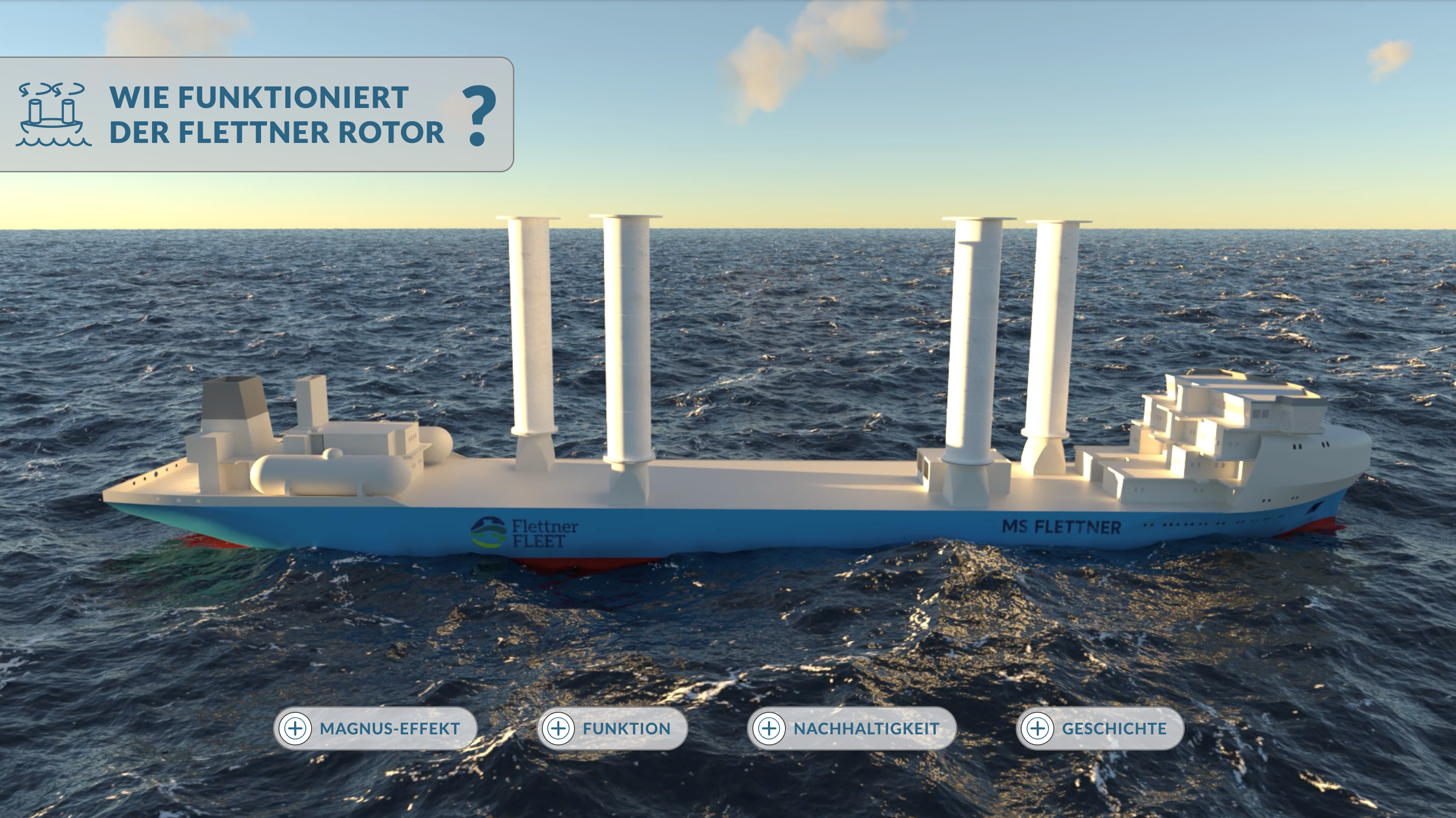

Functional principle

Flettner propulsion uses the wind to generate additional thrust for the ship’s propulsion: A Flettner rotor is a tall cylinder that stands vertically on a ship and rotates around its own axis. It is powered by an electric motor. The interaction between the rotor surface and the wind flow creates a lifting force, giving the ship extra thrust. This not only saves fuel, but also reduces emissions.

Interactive presentation (German)

Requirement: Current version optimised for Google Chrome

Application

Not only saving fuel, but also emissions.

The first ECO-FLETTNER rotor was installed for initial operation on the coastal freighter “Fehn Pollux”, where it was examined in an ongoing endurance test and data was generated.

Insights have been gained into fuel savings, operational safety and reliability, service life and the possibility of integrating wind propulsion systems into existing ship concepts.

The impact on ship operations and cargo handling, the handling of the steering system and the behaviour of the rotor in heavy weather conditions, as well as optimised route planning were investigated and evaluated.

Fuel and emission savings of 15% – 20% were realised for the Fehn Pollux, depending on the sailing area.

Further Information

„Flettner – rotor reduces cost of fuel (German) “

Contact