Content

Measures

How can ships sail efficiently and in an environmentally friendly way? One way is to use wind power to assist the main propulsion – for example with a Flettner rotor. This type of propulsion uses the wind to generate additional thrust for the ship’s propulsion. The FlettnerFLEET project is creating the necessary conditions and foundations for the further development of Flettner rotor technology for the development of ships with this innovative propulsion system.

Create design bases of various cargo ships with Flettnerrotors

Development of design principles

Hydrodynamically optimised underwater hulls

Aerodynamically adapted surface vessels

Coordinated propulsion concept

The aim of the project is to develop a comprehensive methodology for the design of ships with Flettner rotors, in order to enable a wide application of the technology in shipping. To this end, different types of ships will be investigated and optimised for operation with Flettner rotors in cooperation with the shipping companies involved in the project. This will make it easier to transfer the results to actual ship designs.

Dr. -Ing. Jochen Marzi

HSVA – Hamburger Schiffsversuchsanstalt

Further development of the Flettner rotor technology

Optimisation of rotor geometry and mechanics

Investigation of alternative materials

Preparation for industrial rotor production

Analysis and comparison with existing regulations

Ralf Oltmanns

ECO FLETTNER GmbH

“The extremely positive results of our prototype installation are now being used to further develop the technology. With this installation, we already have a good database for the next optimisation steps, which we will now expand even further.“

The data collected will be used to optimise the operation and design of the rotors. This will involve analysing existing designs and developing improvements. A cost-effective and flexible manufacturing process is also being sought. The aim is to build up and maintain manufacturing expertise in Germany.

Optimisation of existing assistance systems

Another element of the project is to optimise the route planning for rotor vessels so that they can make the best use of the wind. However, the aim is not to cover unnecessary extra distances in order to meet schedules. It is also important that the control of the rotors is as simple as possible, but that the systems have a high degree of autonomy and intelligence. This is the only way they can be used as much as possible and thus save fuel. The units need to be well coordinated with each other to achieve further fuel savings.

Prof. Capt. Michael Vahs

Hochschule Emden/Leer

Extensive data collection for a broad data base

MS Annika Braren and MS E-Ship1 as data providers

Data base for further development of rotor technology and ship design

The pioneer of the project is the former “MS Fehn Pollux”, equipped with a Flettner rotor from Leer.

Other rotor ships, such as the MS E-Ship1 and the MS Annika Braren, will also be included in the project’s database during the course of the measurement campaigns. For this purpose, the existing measurement systems on board will be checked and, if necessary, adapted in order to be able to record the relevant data from the rotors. Analyses will help to optimise the Flettner rotor technology and to develop the planned ship designs for the interaction between the Flettner rotors and the system ship.

Paul Feja

Fraunhofer Institute for Wind Energy Systems

“A good database is an essential element for further developments. This is where we bring in our expertise and experience from the wind power industry to advance Flettner rotor technology,”

Events & News

Windship Insights – Focus on Suction Wings

26.03.2025 | Microsoft Teams

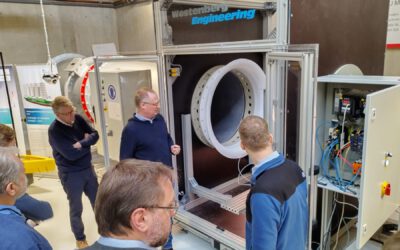

Towing tests of the first ship design

at the Hamburgische Schiffbau-Versuchsanstalt GmbH (HSVA)

Wind propulsion is becoming increasingly popular in shipping

‘Windship Day 2024’ conference on board the historic cargo ship PEKING

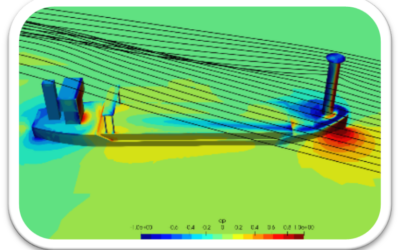

Project update: CFD

CFD, FlettnerFLEET and MS “Annika Braren”

Windship Insights – Flettnerrotor

23.10.2024 | Microsoft Teams

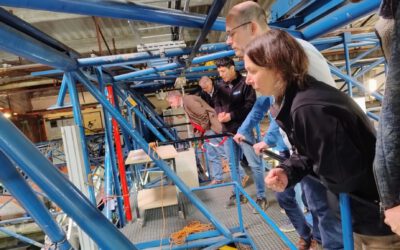

Project update: measurement systems and data acquisition

Installation and commissioning at “MS Annika Braren”

Status-Update FlettnerFLEET

Project meeting no. 3 in Leer

FlettnerFLEET in the spotlight at the National Maritime Conference

FlettnerFLEET was presented to Federal Minister Robert Habeck

FLETTNERFLEET: A fresh breeze for the fleet!

Federal government funds a project to further develop Flettner rotor technology

Downloads

Flyer

Artikel "Flettnerrotor senkt Brennstoffkosten“"

Contact